Plasma Nano Coating

This physical vapor deposition (PVD) process uses plasma ions with high energy in a high-vacuum atmosphere to form a deposition layer of multiple ㎚ to ㎛ on a product surface. It can be used to coat a variety of materials including metals, alloys, and ceramics.

| Item | Plasma Nano Ncoating | Note |

|---|---|---|

| Roughness(Ra) | 4? or higher | Affected by the roughness of base metal |

| Porosity (%) | Less than 0.2% | |

| Hardness(Hv) | - | No surface scratches at 9H of pencil hardness |

| Adhesion(MPa) | 19.9 Mpa or higher | Bonding material separation value (thermal spray layer of16.1Mpa) |

| Volume resistance | 3um(260V,11mA) | 6um(330V,11mA) |

| Color | Translucent yellow | ~10㎛ : transparent 15㎛~ : pale yellow |

| Plasma resistance | Good | 1.4 times as high as Y2O3 thermal spray layer |

| Coating thickness | Multiple nm ~ 20㎛ | Can control thickness in units of Nm |

| Thermal shock | ~ 850℃ | Test completed up to 850℃ |

| Category | Thermal Spray Coating | PN Coating | Note |

|---|---|---|---|

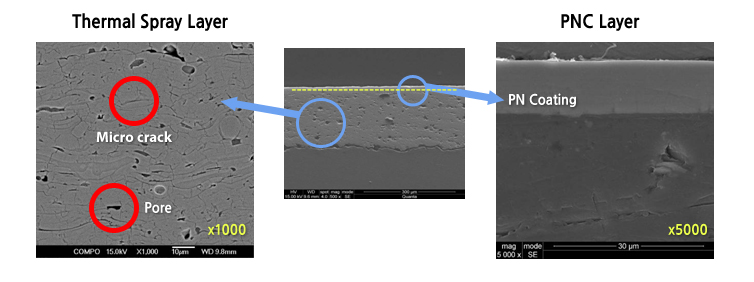

| Porosity (%) | 4% | Less than 0.2% | ※ The lower the porosity gets, the more resistant the plasma gets |

| Micro Crack | Yes | No | ※ The lower the micro crack, the less particles |

| Roughness (Ra) | ㎛ unit | Nano unit | |

| Density (kg/㎠) | 165 | 203 or higher (Re-separation of bonding) | ※ Measurement standard of JIS H 8666 |

| Shield capacity | Good | Completely shielded |

Head Office in Gumi Address : (39422) 39 4gongdan-ro 7-gil, Gumi-si, Gyeongsangbuk-do

Tel : 054-473-8968~70 Fax : 054-471-4781 Email : kstgumi@kst1.co.kr COPYRIGHT (C) 2013 KOREA STAR TECH CO,.LTD. ALL RIGHTS RESERVED.

Tel : 054-473-8968~70 Fax : 054-471-4781 Email : kstgumi@kst1.co.kr COPYRIGHT (C) 2013 KOREA STAR TECH CO,.LTD. ALL RIGHTS RESERVED.