Design & Electrode Manufacturing Technology

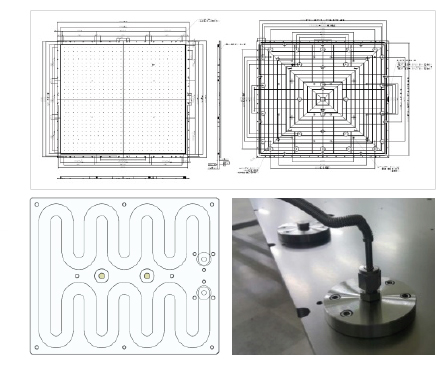

Design Technology

- ESC Electrode Design Technology (Performance)

- LCD 1G ~ 8G ESC Electrode Design

(About 30 Model) - High Power ESC(SUS, Al) Design

(3G, 4.5G, 5.5G) - High Temperature ESC(SUS) Design

(3G, 4.5G, 5.5G)

- LCD 1G ~ 8G ESC Electrode Design

Patent & Specialized Technology

- Electrostatic Chuck reproducing method of TFT

fabrication equipment (Patent 10-0908227) - Large size Electrostatic Chuck and manufacturing

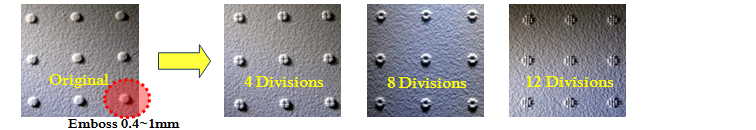

method thereof (Patent 10-1189815) - Constantly changing mask with lower electrode embossed pattern

(Utility Model 20-0452471) - Sintered ceramics DC port making (Patent Application) & clamping technology

- Completion of development of high-resolution powder material (Patent Application)

- Development of a high-quality sealant essential to enhance withstand voltage of plasma coating

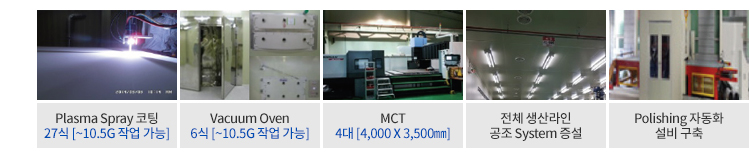

Production Capacity

- Secure consistent quality at world-class level in manufacturing ESC for LCDs

(About 10㎛ of flatness of ceramic surface) - Large-area plasma coating system (3500 X 4500mm) Largest in Korea

- 1000 Class Cleanroom (150 pyeong)

(Large heavy-duty vacuum oven, 3D inspection, packing) - Recyclable equipment (cleaning, removal of thermal spray layers, repairs, manufacturing, etc.)

Head Office in Gumi Address : (39422) 39 4gongdan-ro 7-gil, Gumi-si, Gyeongsangbuk-do

Tel : 054-473-8968~70 Fax : 054-471-4781 Email : kstgumi@kst1.co.kr COPYRIGHT (C) 2013 KOREA STAR TECH CO,.LTD. ALL RIGHTS RESERVED.

Tel : 054-473-8968~70 Fax : 054-471-4781 Email : kstgumi@kst1.co.kr COPYRIGHT (C) 2013 KOREA STAR TECH CO,.LTD. ALL RIGHTS RESERVED.