Thermal Spraying

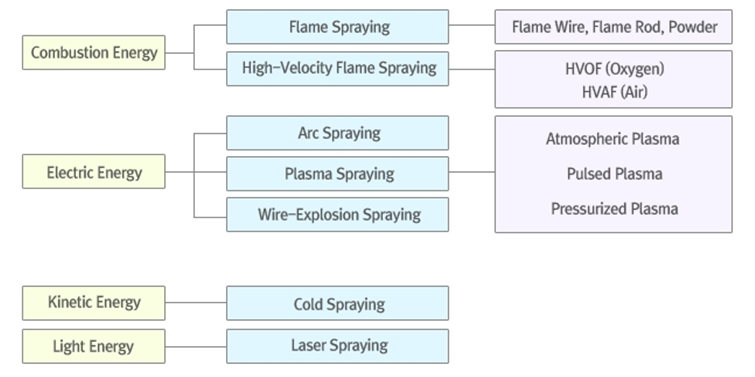

Classification of Thermal Spraying Methods

- Classification by application/purpose

- corrosion-protection spraying, wear-control spraying, thermal barrier spraying, etc.

- Classification by spray material

- Metal spraying, cermet spraying, ceramic spraying, plastic spraying, etc

Characteristics of Thermal Spray

- Provides a wide choice of base metals

- Metals, non-metals, alloy steel, plastics, wood, paper, etc

- Provides a wide choice of spray materials

- Metals, alloy metal, ceramics, plastics, etc. (all materials that can be made into wires and powders)

- Provides fast coating formation

- Flame spraying(15kg/h), arc spraying(6~20kg/h)

- No size limits

- Whether automatic or manual process, no size limits.

- No temporature limits for base metals

- Thermal spraying can be even applied on the site.

- Environment friendly

- Surface coating techniques with low levels of pollution.

Head Office in Gumi Address : (39422) 39 4gongdan-ro 7-gil, Gumi-si, Gyeongsangbuk-do

Tel : 054-473-8968~70 Fax : 054-471-4781 Email : kstgumi@kst1.co.kr COPYRIGHT (C) 2013 KOREA STAR TECH CO,.LTD. ALL RIGHTS RESERVED.

Tel : 054-473-8968~70 Fax : 054-471-4781 Email : kstgumi@kst1.co.kr COPYRIGHT (C) 2013 KOREA STAR TECH CO,.LTD. ALL RIGHTS RESERVED.